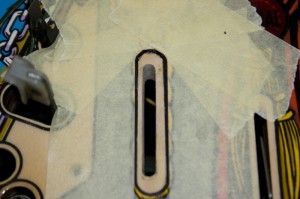

The hole under the electric chair gets a lot of use and abuse during normal play and is always the first hole to show wear and tear. With time this wear becomes extremely ugly. And with it (almost) being in the centre of the playfield, it’s not exactly something you can miss whilst playing:

Typically damaged outhole under Uncle Fester's chair

There are two alternative to protect this highly vulnerable area: firstly, a so called “Cliffy Protector”:

A Cliffy protector for the Electric Chair hole

which clips onto the hole and is held in place by the screws for the chair bracket:

A Cliffy Protector mounted onto the playfield

It certainly looks good! Of course the advantage of this is that it covers up the damaged hole as well as protecting it from further damage. The disadvantage is, well, that it isn’t original.

The second alternative protector looks like this:

Hole Guard protector

This part mounts from the underside of the playfield and protects the playfield when the balls are kicked out of the hole. This part can’t be seen when inserted into the machine and just does its job, leaving the playfield looking more authentic.

I chose to go with the second option (not only to have the playfield as authentic as possible, but also to show off my touch up!) on the understanding that if the conditon of the hole degraded in any way in the future, then I could always install a Cliffy protector afterwards.