Well I got the playfield and all the boards connected up today – it all seemed to make sense actually, which was a good feeling and I discovered in the process, that I had actually incorrectly marked up two of the female plugs! I also managed to plug J105 onto J106 by mistake and in trying to take it off again, broke two retainers off of the male part on the PCB (which I had so carefully soldered onto the board), so I just left it on there. It turns out that I will be needing to plug J105 onto J106 for the “black-out” mod anyway, so that’s another reason why it can stay on there for now (both connectors are connected in parallel to one another).

I attached the outlet cable into the back of the machine, the loudspeaker panel and then (very nervously) switched the machine on.

The GI lighting came on and a message kept repeating in the display, in French. There was no smell of smoke.

So I turned the machine off, turned the “country” dip-switches 7 and 8 on the CPU board to “off” and switched the machine back on agian. The GI lights came on and the message came up in English. Something about the book keeping numbers being reset, or something. Not a surprise really, as I had already taken the batteries out of the CPU before cleaining it and connecting it in to the machine.

So I went into the test menu and tested everything I could test and everything passed with flying colours – apart from two small issues:

1) the metal ring of the lower jet bumper would not return to the upper position once activated. At first I thought the coil was permanently on and panicked, switching the machine off. I then remembered that as I was putting the jet bumpers together, one of the bumpers had a spring in it, which was notably weaker than the other two. I made a mental note at the time. This weaker spring was in this lower jet bumper. So I switched the machine back on, went through the test menu again until I got to the lower jet and put it into test mode. As the metal ring was drawn down I applied a little pressure to lift it again and once the coil had deactivated, sure enough, the ring popped back up. So I obviously needed the right spring.

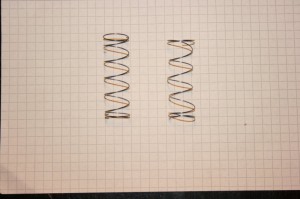

Now according to numerous shops, there are two “suitable” springs for the pop-bumper a 10-326 and a 10-135. However, looking into it a bit deeper, the 10-326 is used in the pop-bumpers only and the 10-135 almost everywhere else (for WPC machines). I suspect I have a 10-135 in the pop-bumper and require a 10-326.

Incidentally, why the metal ring doesn’t return even with the weaker sping is something I find peculiar: when the coil de-activates the ring stays down; by applying a slight pressure under the ring it then pops up again. But then trying to get the ring to stay down again manually is impossible, with the spring returning the ring to the upper position every time! So I’m guessing that when the coil activates it draws the plunger down until the plunger hits the end-stop. When the current is removed from the coil so that the magnetic field collapses, there must be a residual magnetism in the plunger and coil stop which holds them together. As soon as this bond is broken however, the residual magnetism dissapears. Sounds plausible. The spring therefore needs to overcome this force of attraction and that caused by the weight of the ring. If it is unable to do this, the ring stays down until broken manually. Solution: stronger spring (I verified this by temporarily using two 10-135 springs instead of just one – thereby doubling the return force, which worked).

2) The second problem was also interesting: in testing the lamps in “all lamps+flasher” test the left flipper bat activated in time with the strobing lamps. It also activated with the strobing lamps in the “all lamps” test. But I couldn’t get it to activate in the “single lamp” test or the “column/row lamp” test. Also activating the flipper using the flipper button didn’t light up any lamp(s). I’ll investigate this one later….