Following the identification of the initial problems reported in my last post, closer inspection has now revealed other issues:

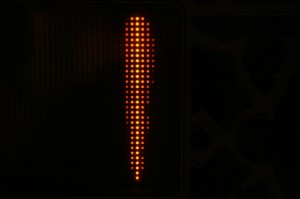

1) The Dot Matrix display has two columns (127 and 128) which aren’t working

2) The blue oblong (bear kicks) target is physically broken

Bear Kick Target

3) One of the two graveyard targets has its spongue padding missing

Spongue missing

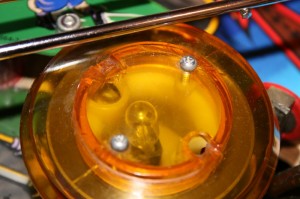

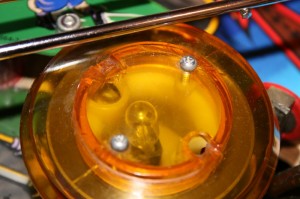

4) One of the jet-bumpers (blue) isn’t functioning

5) The jet-bumper plastics are fractured at the mounting holes

one of the fractured caps (note the repair already carried out)

6) The plastic (staircase) ramp is fractured at several mounting holes

A fracture on the main plastic ramp

7) Several of the post-rubbers are old and flaking (in particular the yellow tapered bumper and two of the black rubber sleeves)

A well worn yellow post

A worn rubber post

Well worn (old) rubber

8) One of the 3/4 inch rubber rings is broken

Broken rubber

9) One of the 3/4 inch rubber rings is completely missing

Here was once a rubber

10) Both blue rubber pads on the elevated ramps are missing.

Missing rubber on right ramp ball drop

Missing rubber from left "Thing" ball drop

11) The bookcase is fractured in several places

Crack on bookcase

Crack on bookcase plate

12) There is evidence of “magnet burn” on the playfield (lower left magnet)

Example of magnet burn

13) Where the playfield would appear to be “burned” some of the paint has flaked away.

Flaking paint under burn (click picture to enlarge)

14) The paintwork around the power insert has been worn away

Worn paint to bare wood around The Power insert

15) The paintwork under the ramp drop on the right flipper lane is damaged

Worn paint to wood under ramp drop on right side

16) The edges of the mylar protecting the playfield have accumulated dirt and don’t look too good

Typical accumulated dirt under Mylar

More dirt under Mylar

17) The playfield surface around the electric chair hole is severely damaged

Typically damaged outhole under Uncle Fester's chair

18) The pinball shooter is damaged

Chipped shooter

19) The front of the pinball has paint removed (following removal of stickers, I assume)

Black paint removed around sword/logo and an extra decal

20) The transfers on the apron (or bridge or arch) have been worn away badly

Badly worn decal on left side of arch

Badly worn decal on right side of arch

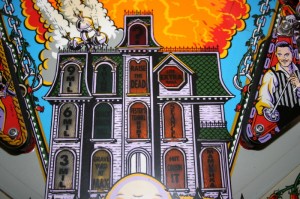

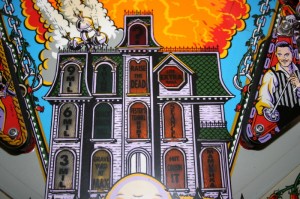

21) The plastic around the inserts in the mansion is worn away (although this is to be expected in a machine of this age)

The house showing some damage around the inserts

Considering the description of the pinball on Ebay (see the introduction page) I find it incredible that the pinball has been delivered in this condition. Despite the fact that the pinball I have received is not as described in the auction, the time and effort which I have invested to-date (including getting the pinball machine down into the cellar) make it very difficult for me to return the pinball machine to the seller. As such I have decided to try to work with the seller to alleviate as many of the problems as possible and at the same time to renovate the machine as well as I can.