The lockbar came under the spotlight today. The top surface was scratched really badly and underneath was a disaster – the stainless steel being stained a brown colour and the beer seal being crispy from what must have been years of abuse!

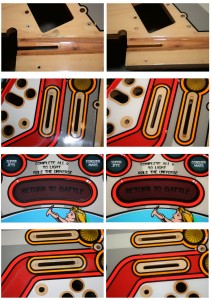

Condition of lockbar (below) originally

I wasn’t going to do much with the lockbar apart from clean the underside and replace the beer seal. However, quite recently on my local forum, there have been threads concerning the polishing of stainless steel parts. The results have been really impressive, so that I’m now considering polishing my stainless steel parts also. It turns out that the lockbar is also stainless steel, which means that I could actually practise polishing stainless steel using the lockbar as my test piece. After all, if it went wrong, I could simply buy a new one.

So firstly, I took some 120 grit sandpaper and sanded out as many scatches as I possibly could from the lockbar, remembering to sand only along the grain in one direction. Once I thought I had removed most of the scratches I moved onto 400 grit paper and continued to sand in the same direction, until the surface appeared uniform. Next was 600 grit, which I used wet, once again remembering to sand in the same direction.

After over 2 hours of sanding and sweating I was done. And this is how it turned out:

Lockbar sanded to 600 grit

I was amazed at how good it looked! I was really tempted to take it down to 800 grit and then 1000, but close inspection of the lockbar shows that I didn’t get rid of all the initial scratches, meaning that if I went to a finer grit those scratches would become more obvious. And if it turned out really nice, I would then be over protective of my lockbar and probably not allow anyone to play the game! Finally, bearing in mind that although new, the side rails are also not highly polished, so the difference between lockbar and side rails might look silly if too extreme.

Next came the underside. Using fat remover I was able to clean up the underneath quite well and the crystalised beer seal came of reasonably easily. In trying to clean up the zinc plated retainer, however, I managed to remove some zinc plating. Not wanting the retainer to rust any time soon I decided to spray paint it with zinc paint.

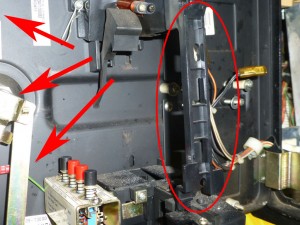

It turns out, however, that this spay paint doesn’t like cold temperatures and should be applied with an ambient temperature of above 20 deg C. Well it’s 1 deg C outside these days – with the onset of winter – so that I couldn’t go into the garage to spray the part. So I make-shifted a spray cabin and sprayed in the cellar:

Lockbar all wrapped up, exposing the zinc plated retainer, in a portable spray cabin (a cardboard box)

And the results, having added a new beer seal, weren’t bad either:

Underside of lockbar with freshly sprayed retainer