Flasher Problems – continued

Sunday, June 14th, 2009I took out my old Power Board yesterday and replaced with a new one I had bought last year from PinLED. I fired up the pinball machine and tested the flasher circuits. Same problem was apparent (maybe I should have tested the pinball with this board before replacing components? Another lesson learned).

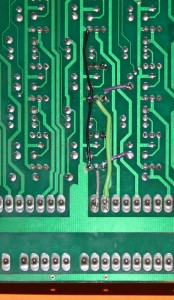

So today I rigged up a flasher lamp tester and connected it to the +20V Test Point on the power board and poked the other end in J126 pins 1 through to 6 in turn (these are the “grounding pins” for the flasher circuits) whilst the lamps+flasher test was in progress. The test flasher flashed for every pin, which implies to me that everything is working as it should at the board level, but at the playfield level it is somehow getting screwed up.

Whilst prodding about under the playfield I also found a connector which had a red/white wire attached to it (the 20V DC line) as well as the black/red and black/brown wires. These are the “ground” wires for the rear flasher circuits. I disconnected this connector and then tested each flasher. Interestingly only one of the flashers of each pair now flashed (implying to me that each flasher pair is fed from a different 20V DC line from J107 (pins 5 and 6) and that

I had now disconnected one of these feeds).

However, interestingly, during the individual flasher circuit test, when it came to the Left Lightning Bolt/Mini Flipper pair of flashers, both flashed, Also when it came to the Right Lightning Bolt/Swamp Flashers, the Right Lightning Bolt and the Mini Flipper flashers flashed – this should definitely not happen! (With the connector connected again, this phenomena was no longer present).

So something appears really screwed up with the flasher wiring which I just don’t understand……yet. Also, in order to test the flasher circuitry at the playfield end requires the flasher bulbs to be removed. As this is not so easy for three of the flashers, I’ve decided to leave this testing until I’ve started to remove the parts from the playfield (for the renovation).