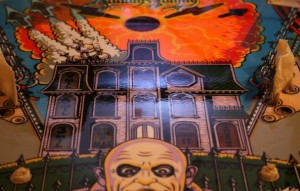

The bookcase base

Sunday, April 18th, 2010It’s always struck me as funny, why the bookcase and bookcase base are blue. The blue just doesn’t suit the game in my opinion – especially the base.

There are of course, decals which you can buy to stick onto the base to blend in with the playfield. But based on my experience, the colours are all wrong and/or the size of the decal is wrong.

So I decided to paint my new bookcase base.

As I have a scan of a bookcase decal, I used it to separate the three colours (grey, yellow and black) in Photoshop, create some masks with my CraftRobo plotter and paint the base using these masks and my airbrush.

Prior to spraying the base, I sanded it down with 1200 grit wet and dry sandpaper. I then spray-painted the grey colour and left it to dry.

In Photoshop it was quite easy to separate the colours. Having got the yellow and black shapes separated, I increased their size by four pixels in order to help me prevent having grey streaks between the black and yellow shapes (which could always happen if the masks weren’t aligned properly).

Before cutting the yellow mask, I decided to simplify the masking process by joining up as many of the yellow “islands” as possible, making sure I joined these islands underneath where the black paint would be applied. Without this, or so I thought, applying the mask would be very difficult. I then cut the mask.

Using the raised ridge on the bookcase base as a guide, I placed the yellow mask onto the base. This wasn’t as easy as I had thought, as the fact that I had joined up all of the “islands” actually made the process even harder! However, I perservered and using a ruler I managed to get the mask applied to the base. Spray time!

Finally, I repeated this procedure with the black mask. This was, however the most difficult as the mask was made up itself of little masking islands, which are very difficult to apply. No wonder no-one else does this on their bookcase base!

Having applied the black mask, I noticed that the alignment with the yellow wasn’t perfect, so I made a few manual adjustments to the mask before spraying the black paint.

I now just need to apply a clear coat to this and then I’m done!